ABB Fibre Tester Helps to Create High-quality Paper for Structure, Insulation and Soundproofing Materials

- Mechanical defibrated cellulose nanofibre (CNF) paper from Japanese paper manufacturer Kami Shoji, Ltd. features superior strength and elasticity

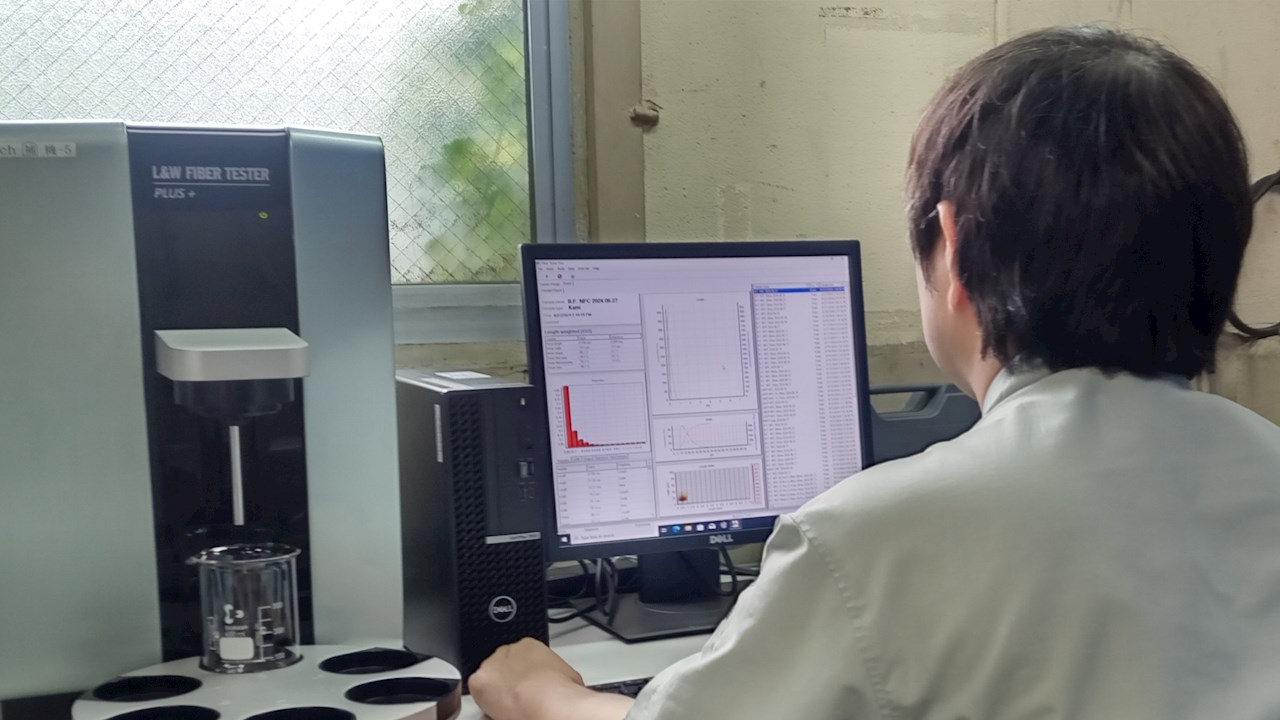

- ABB L&W Fibre Tester Plus accelerates paper defibration testing by enabling customer to observe 20,000 fibres in just ten minutes

- Customer benefits from fast measurement speeds and precise and reliable measurement data

Specialist Japanese paper manufacturer Kami Shoji Co., Ltd. has taken delivery of ABB’s automated testing solution L&W Fibre Tester Plus, which offers quick and easy measurement of fibre quality as well as advanced analysis of fiber morphology. Kami Shoji will use L&W Fibre Tester Plus to conduct defibration testing on its cellulose nanofibre (CNF) paper production to find suitable production conditions.

Defibration is the process of separating wood fibres from each other prior to entering the paper machine. Kami Shoji’s production method for CNF paper is known to be more cost-competitive than ordinary chemical defibrated CNF production. The company developed its own special press method which enables faster dewatering time in the production of amorphized CNF paper. It results in a product with the same strength and environmental resistance as chemical CNF paper in oily environments.

Kami Shoji’s CNF paper has good elastic deformation to alter the material’s shape, which is not possible with regular chemical CNF paper. The paper, having unique strength properties, is expected to be used for structure, insulation and soundproofing material.

The process of making mechanical defibration CNF paper is considered challenging and depends on efficient, accurate visual inspection of the fibres to assess the degree of defibration and the optimum refiner conditions. Using ABB’s automated fibre morphology analysis device, ABB L&W Fibre Tester, the customer can observe an average of 20,000 fibres in just ten minutes – something that is impossible with manual inspections using an optical microscope – and produce multiple measurements including the fibril perimeter.

Kami Shoji has used L&W Fibre Tester Plus extensively for the criteria of fibre conditions required for research and development of CNF paper. We are very satisfied with the device, which provides extremely valuable measurement results during CNF research.

Shosaku Kashiwada, Ph.D., Acting General Manager of Development Plan Section, Kami Shoji Co., Ltd.

“ABB L&W Fibre Tester Plus is already being used by major Japanese public institutions in Shizuoka, Gifu and Kochi, where many pulp and paper companies are situated, thanks to its proven ability to quickly and accurately extract valuable raw paper defibration data to inform advanced research,” said Hiromichi Yoda, Local Division Manager, Process Industries at ABB in Japan. “ABB is positive about extending collaboration with specialist paper producer Kami Shoji, who will continue to benefit from optimised operation conditions at its facilities, leading to improved quality control, productivity and stable production.”

L&W Fibre Tester Plus uses image analysis to measure fibre length, width, fines (primary and secondary), shape factor, microfibrils and coarseness. Software and hardware modules for crill are available as well as software modules for vessel cells, minishives, local deformations (kink) and fibre mix calculations. It also features a deaeration process for more accurate measuring.

About ABB’s Process Automation

ABB’s Process Automation business automates, electrifies and digitalises industrial operations that address a wide range of essential needs – from supplying energy, water and materials, to producing goods and transporting them to market. With its ~20,000 employees, leading technology and service expertise, ABB Process Automation helps customers in process, hybrid and maritime industries improve performance and safety of operations, enabling a more sustainable and resource-efficient future. go.abb/processautomation

About ABB

ABB is a technology leader in electrification and automation, enabling a more sustainable and resource-efficient future. The company’s solutions connect engineering know-how and software to optimise how things are manufactured, moved, powered and operated. Building on over 140 years of excellence, ABB’s more than 105,000 employees are committed to driving innovations that accelerate industrial transformation.