Redefining Energy Efficiency in Paper Production

By: Emre Bilgin, Sales Paper Industries, MAN Energy Solutions

The paper industry is currently undergoing a shift due to rising energy costs and the urgent need to reduce its carbon footprint. While companies are streamlining production systems to increase their competitiveness, they are also prioritising energy saving, sustainability development, and diversification into new business areas, such as the development of innovative products.

In 2023, the production of board and packaging paper surpassed 265 million tons, with forecasts predicting an average annual growth rate of around 4,6%. As sustainability and environmental responsibility gain importance, the industry is not only adopting eco-friendly materials but also focusing on optimising energy use in the papermaking process. One of the most energy-intensive stages in paper manufacturing is dewatering the paper roll, where vacuum systems account for 20-25% of the total electrical energy consumption.

Using vacuum systems for greater energy efficiency

TURBAIR® vacuum systems, developed by MAN Energy Solutions in Switzerland, are designed for energy efficiency and sustainability. Unlike conventional water ring pumps, which tend to wear out and lose efficiency over time, these vacuum blowers offer more consistent performance. In conversion projects, energy savings typically range between 40% and 60%. Additionally, these vacuum systems consume up to 30% less energy than conventional water ring pumps, thanks to their unique design that eliminates friction losses caused by the water ring.

The TURBAIR® blowers are engineered to operate efficiently across a wide range of conditions – including partial load scenarios – which can lead to additional energy savings of up to 30%. With frequency-controlled drives, these blowers offer flexible control over air volume and vacuum levels, allowing operators to adjust them to the specific needs of the paper machine. This not only helps to prevent unnecessary energy loss due to over-expansion, but can also result in an additional energy reduction of up to 20%, depending on the process requirements. Moreover, TURBAIR® technology eliminates the need for sealing water, resulting in further cost savings and reducing the system’s environmental impact. By removing the need for sealing water, the blowers contribute to a more sustainable and eco-friendly operation.

“The TURBAIR® vacuum systems stand out for their unmatched efficiency and reliability. A major advantage of this system is the ability to harness the hot exhaust air from the blowers with a heat exchanger, leading to even more energy savings. The exhaust air temperature of these blowers typically ranges between 120°C to 165°C. As a rule, approximately 70% to 80% of the blower’s drive energy can be recovered through waste heat,” said Manfred Dobler, Head of Paper Industry at MAN Energy Solutions.

Considering the potential savings mentioned, paper manufacturers can significantly reduce energy consumption of the vacuum system by up to 80%.

Versatile vacuum blower solutions

To meet the different needs of papermaking, single-stage RT or multi-stage RC blower types are available in different sizes:

Single-stage RT blower:

The RT vacuum blower has a capacity range of 200 to 1,450 m3/min, with a pressure of up to 62 kPa. Thanks to its automatic outlet regulation, the flow rate can be dynamically adjusted to the demands of paper machines. This versatility makes the RT series especially suitable for felt conditioning in tissue production.

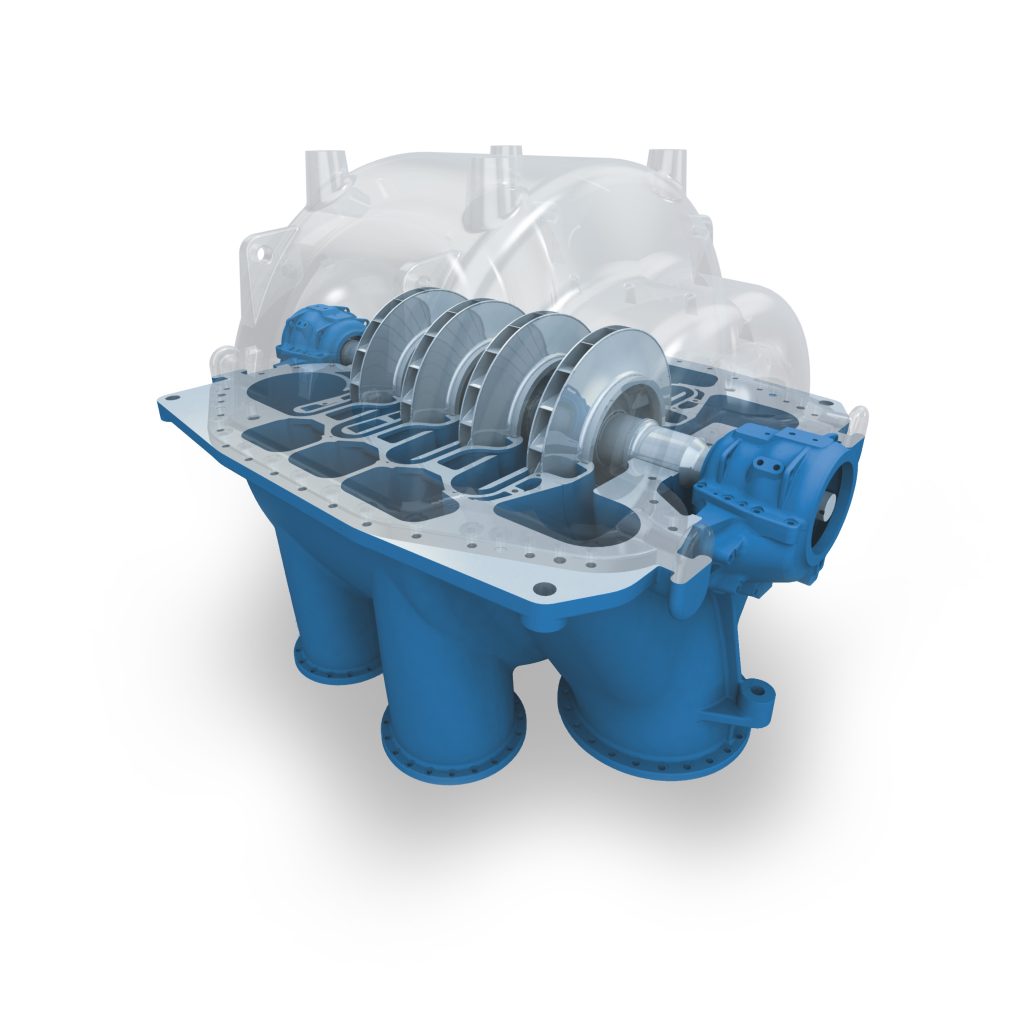

Multi-stage RC blower:

The RC vacuum blower provides a wide capability range, from 180 to 2,800 m3/min with a vacuum of up to 75 kPa, and is equipped with up to four suction nozzles and four vacuum levels. This enables effective operation across all vacuum levels in the wire and press sections.

The RC blower is designed for high-demand scenarios and is well-suited for systems used in graphic paper, cardboard, or pulp production. Its multi-stage radial design ensures consistently high vacuum levels.